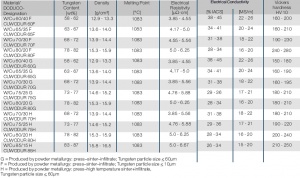

Consisting of pure tungsten w powder suspended in a matrix of copper cu these alloys are readily machinable and known for good thermal and electrical conductivity low thermal expansion being non magnetic good performance under vacuum and resistance to erosion from arcing.

Copper tungsten thermal properties.

Very good thermal conductivity.

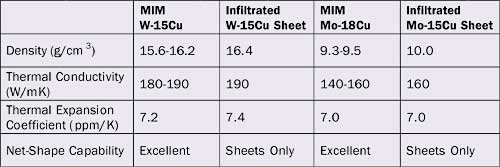

Tungsten copper heat sinks they are composites of tungsten and copper.

Tungsten copper combines many typical characteristics of the single elements tungsten and copper as for example the hardness wear and burn off resistance of tungs ten together with the good electrical and thermal conductivity of copper.

3 show the thermal conductivity measurements of the w cu alloy with the recommended tprc value the thermal conductivity of tungsten was 174 w m k and that of copper was 401 w m k at room temperature and the measured thermal conductivity was between 179 w m k and 238 w m k depending on the copper content due to the higher thermal conductivity of copper the.

Thus they are often used as electrical contacts particularly in high voltage applications.

Copper infiltrated tungsten boasts such properties as high resistance to high temperature and arc erosion excellent thermal and electrical conductivity and a low cte coefficient of thermal.

Copper tungsten or wcu alloy also known as trade names elkonite is a composite matrix of tungsten and copper which combines the excellent properties of the elements such as heat resistance ablation resistance low thermal expansion and excellent thermal and electrical conductivity.

Tungsten copper has unique material properties.

By adjusting the content of tungsten we can have its coefficient of thermal expansion cte designed to match those of materials such as ceramics al2o3 beo semiconductors si and metals kovar etc.

Typically they are malleable and ductile deforming under stress without cleaving.

Contents of tungsten respectively copper can be selected.

The high thermal conductivity of copper together with the low thermal expansion of tungsten allows thermal expansion matching to silicon gallium arsenide and some ceramics.

The physical and mechanical properties and melting point of tungsten copper material will be positively or oppositely affected by varying the amount of.

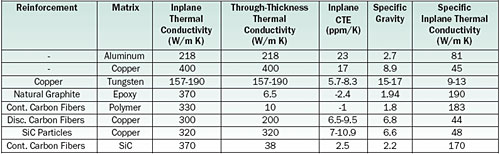

Engineering thermal properties of metals conductivity thermal expansion specific heat data metals in general have high electrical conductivity high thermal conductivity and high density.

A high level of temperature resistance is one of the most important advantages of tungsten while the copper content increases the electrical and thermal conductivity.